Lágyacélok öregedésének elemzése hajlítóvizsgálat alapján

Absztrakt

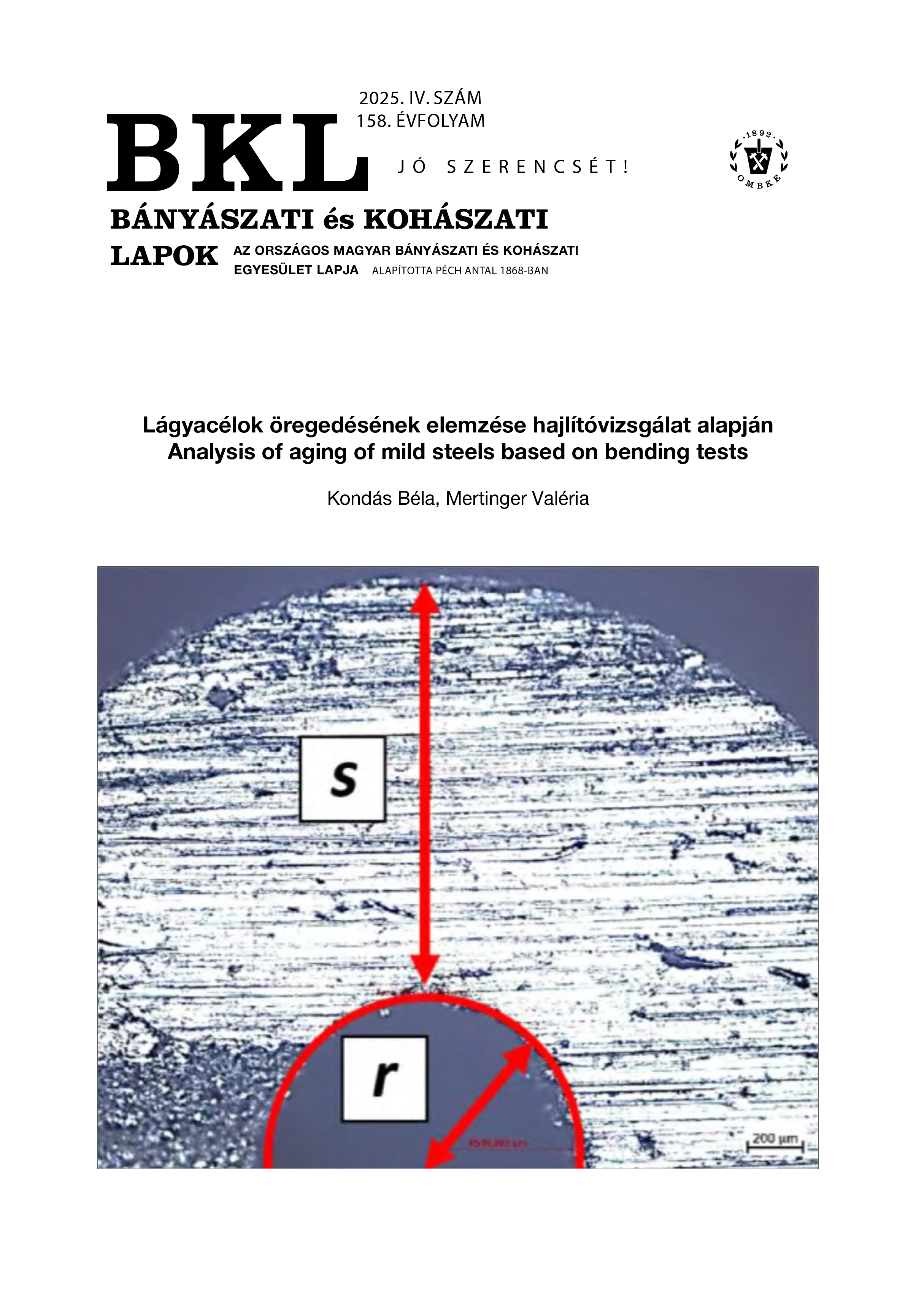

A lágyacél lemezek alakíthatósága már rövidebb tárolási időt követően is leromolhat az öregedési jelenség következtében. Mivel az öregedés dinamikája nem egyenletes ezért ugyanazon adagból származó lemeztáblák mechanikai tulajdonságai is különbözhetnek egymástól, amely az automata megmunkáló berendezéseknél gyakori paraméter utánállítást, hosszabb ciklusidőt, megemelkedett selejtképződést okozhat. Cikkünkben a feldolgozóipar számára olyan egyszerűen végrehajtható hajlítóvizsgálati módszert mutatunk be, ami megbízhatóan jelzi az öregedést. Kísérleteink során DC01 jelű lemezpróbatesteket vetettünk hajlítóvizsgálat alá gyártásukat követő tíz időintervallumban. A vizsgálat megfelelő szintű érzékenységének biztosítása érdekében az értékelési kritériumokat a szabványkövetelményekhez képest tovább szigorítottuk, mely által egy költséghatékony vizsgálati módszert kaptunk.

Hivatkozások

A. Hrivňák, L. Sobotová (1992): The influence of the deformational ageing and the conditions of stress on the properties of the deep-drawing steel sheet. Journal of Materials Processing Technology, 34(1–4), 425–430. https://doi.org/10.1016/0924-0136(92)90137-h

A. N. Bhagat, S.-J. Baek, H.-C. Lee (2008): A simple method for prediction of shelf life of bake hardening steels. ISIJ Int., 48(12), 1781–1787. https://doi.org/10.2355/isijinternational.48.1781

DIN EN 10130 (2007): Cold Rolled Low Carbon Steel Flat Products for Cold Forming. Technical Delivery Conditions. Deutsches Institut für Normung e.V.

ASTM E290 (2022): Standard Test Methods for Bend Testing of Material Ductility, American Society for Testing and Materials.

JIS G3141 (2017): Cold Reduced Carbon Steel Sheets and Strip, Japanese Standards Association.